The pre-owned electronics market is entering a new phase. Volumes continue to rise, margins tighten, and customers demand clearer proof of device quality before they buy. In this environment, the businesses that succeed are those that can guarantee consistency — not occasionally, but with every device and across every location. NSYS builds this consistency directly into diagnostics, inventory, and workflow tools, creating a foundation for transparency, trust, and stronger commercial results.

From manual judgement to verifiable quality

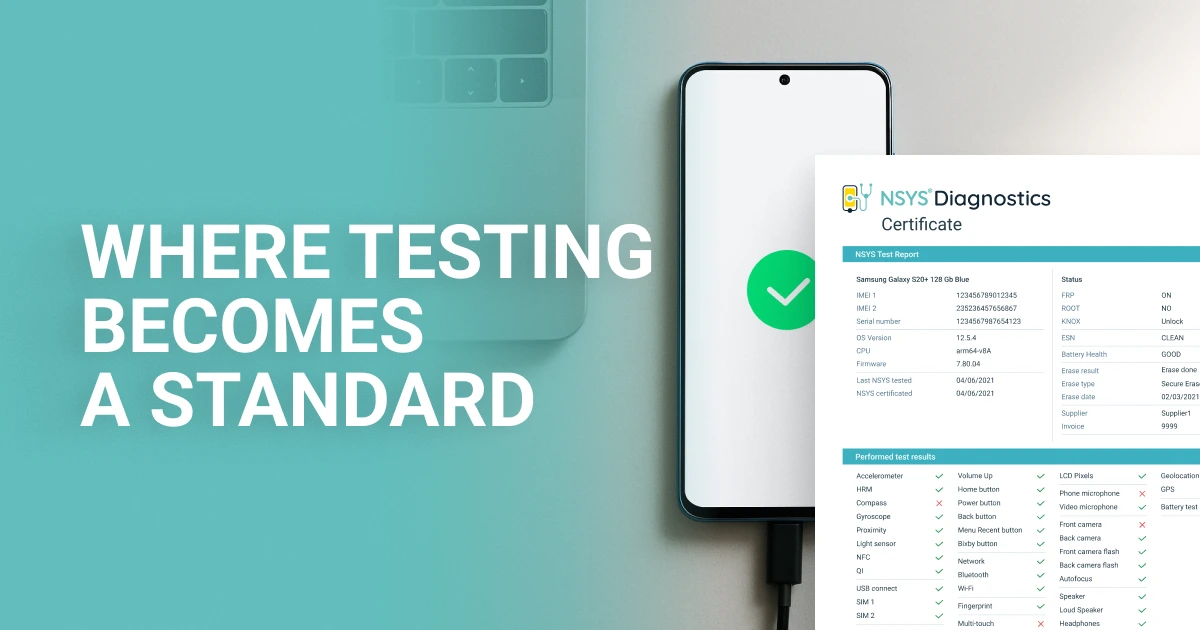

Traditional device testing relies heavily on subjective inspection: what one technician identifies, another might overlook. This makes grading uneven and increases disputes, especially when devices move between refurbishers, wholesalers, and marketplaces. NSYS removes this uncertainty by embedding standards into automated diagnostics.

NSYS Diagnostics runs more than 60 automated and semi-automated checks on iOS and Android devices and identifies over 100 defect types. Each test is documented in a machine-readable certificate that shows the exact condition of the device — from battery cycles to screen response to sensor performance. Because the process is structured and repeatable, businesses get predictable quality, fewer errors, and faster turnaround.

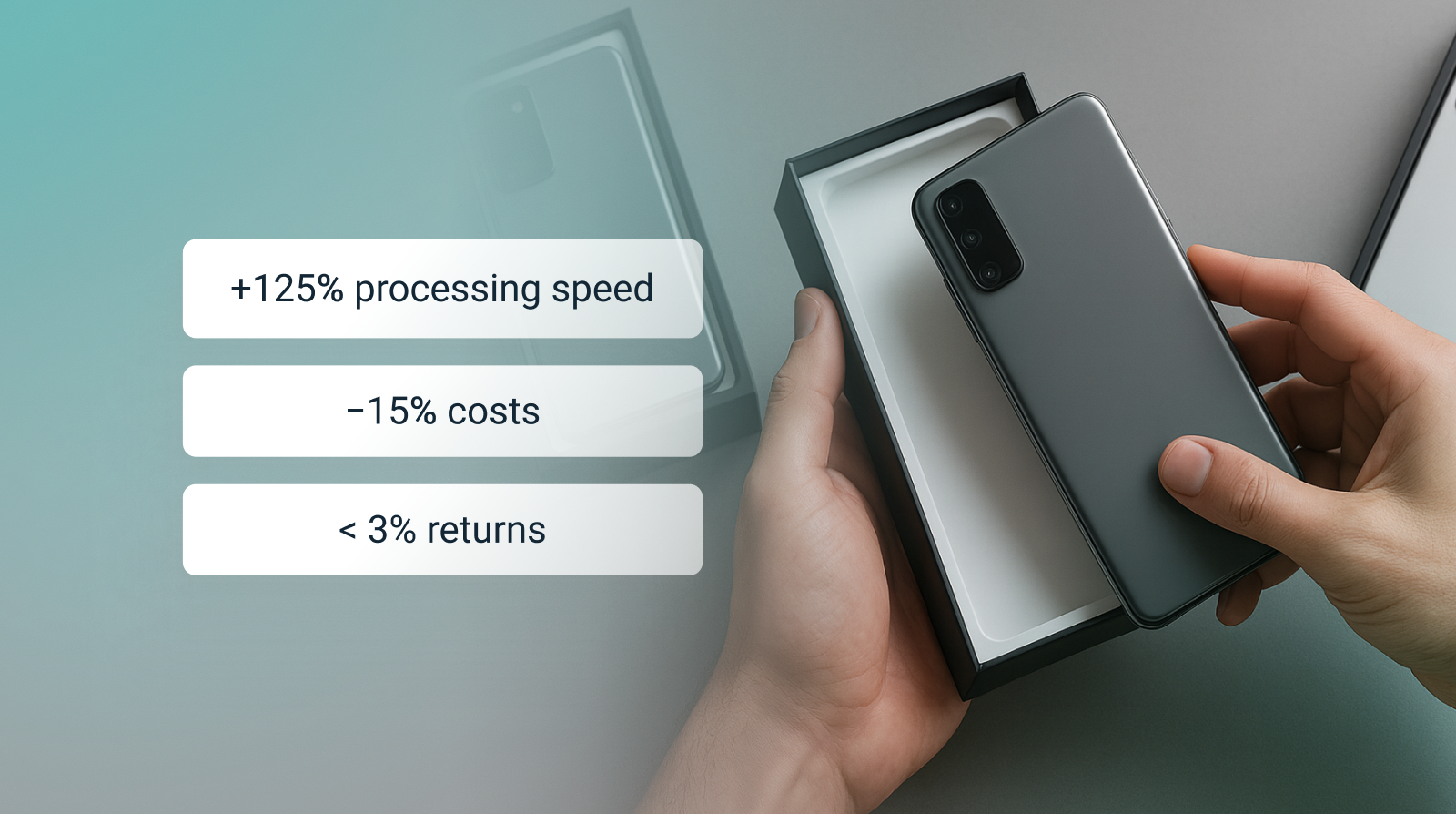

The impact is measurable. After switching from manual inspection to NSYS Diagnostics, Tech2Com increased processing speed to 60 devices per hour and cut its return rate to below 3%. Every device now carries a diagnostic history linked to its IMEI, giving buyers and sellers traceable evidence of quality and eliminating the guesswork that often leads to margin losses.

Standards aligned with real business workflows

Diagnostics alone are not enough unless the results can flow smoothly through operations. That is why NSYS connects testing, grading, and inventory into one ecosystem.

NSYS Inventory enables IMEI-based tracking, consolidates stock from multiple warehouses, stores diagnostic results, and uses APIs to transfer device condition data directly into ERP or inventory systems. Whether a company runs a single location or a network of facilities, every device follows the same standard, and every employee works with the same verified information. This eliminates double testing, reduces operational friction, and ensures quality stays consistent regardless of scale.

This combination of automated diagnostics and unified inventory management creates a transparent chain of data — the kind of reliability that marketplaces and B2B partners increasingly expect.

Making circularity commercially viable

Reliable standards do more than improve internal processes: they strengthen the circular economy. Transparent diagnostics help companies decide whether a device should be repaired, resold, or recycled, ensuring that each unit takes the most profitable and environmentally sensible route.

NSYS tools, including AI-assisted grading and robotics for testing and repair, minimise unnecessary replacements and reduce the number of devices that return due to undetected issues. Certified data erasure further reduces compliance risks. All of this lowers waste, cuts carbon impact, and creates a more predictable, cost-efficient reuse cycle.

Certification that builds trust at scale

The value of a standard grows when partners adopt it. NSYS works with refurbishers, marketplaces, and retailers to make consistent device certification an industry expectation.

After integrating NSYS solutions, ProMobi increased device processing speed by 125% and reduced operating costs by 15%. Buyers receive trustworthy certificates that clearly show the device’s condition, which increases conversion and reduces disputes. Sellers get fewer returns and higher pricing accuracy, strengthening the entire secondary market.

When transparency becomes a business advantage

Standardised testing, grading, and data-erasure workflows generate KPIs that are easy to measure:

• reduced return rates

• faster device turnaround

• higher marketplace conversion

• lower operational risk

Because standards are embedded in the tools, teams don’t need extra training or complex policies — the system enforces consistency automatically. This makes NSYS standards not just operational guidelines but a new benchmark for reliability in the secondary device market.

Why NSYS standards work

Built-in consistency. Automated diagnostics ensure the same test is performed the same way every time.

Seamless integrations. APIs allow data to flow without manual work or duplicated checks.

Sustainability with ROI. Better diagnostics reduce waste while increasing resale value.

The path forward

Raising standards is an ongoing process, and NSYS continues to expand what transparency can look like — from browser-based diagnostics to AI-powered defect detection and new certification formats. As the industry grows, these capabilities will shift from being advantages to being expectations.

Automated testing that provides clear, verifiable device condition data — supported by a certificate — creates a level of trust that the market has long lacked. Businesses that adopt this approach win twice: consumers gain confidence, and companies gain higher margins, stronger brand reputation, and a more scalable, profitable operating model.