In the buyback and refurbishment industry, mobile phone diagnostics are considered a basic part of the workflow. Yet the biggest business risk is not the lack of diagnostics — it is the reliance on inaccurate ones. Small mistakes at the testing stage often look harmless, but over time they become a structural source of financial loss and unpredictable quality.

The impact of inaccuracy rarely appears immediately. Errors are scattered across the workflow and surface only after the device reaches the end customer — in complaints, return requests, and failed batches. Because these problems show up late, companies often disconnect them from their real cause: inconsistent diagnostics.

Why Inaccuracy Remains Invisible

Most teams see only the symptoms, not the root. A device returned with a battery complaint, a dispute over screen condition, or a claim of unexpected functional issues is usually handled as an isolated case. But when manual or semi-automated testing varies by operator, location, or workload, the accumulated variation becomes a hidden operational burden. The company keeps investing in reprocessing and customer support, without realizing the diagnostic step is generating the majority of avoidable errors.

A real example illustrates this clearly. Eminence Corporation achieved a threefold reduction in return rates after moving from manual assessments to automated, standardized diagnostics. The improvement did not come from changing device sources or customer segments — only from increasing diagnostic accuracy. (NSYS)

How Inaccuracy Affects Profit and Reputation

Financially, inaccurate diagnostics express themselves in three ways: higher return rates, increased OPEX, and an inflated cost per processed device. Even a few percentage points of diagnostic variation become significant when multiplied across thousands of units. What looks like margin fluctuation is often a direct consequence of unstable testing.

But the deeper impact is on reliability. Large resellers, operators, and enterprise buyers value consistency above price. When the stated condition of a device does not match reality, confidence in the supplier erodes quickly. One unstable batch can lead to slowdowns in procurement, tougher contractual controls, and reduced willingness to commit to long-term agreements. Reputation in the secondary device market is cumulative; it is built on every batch that arrives exactly as promised — and damaged by every batch that does not.

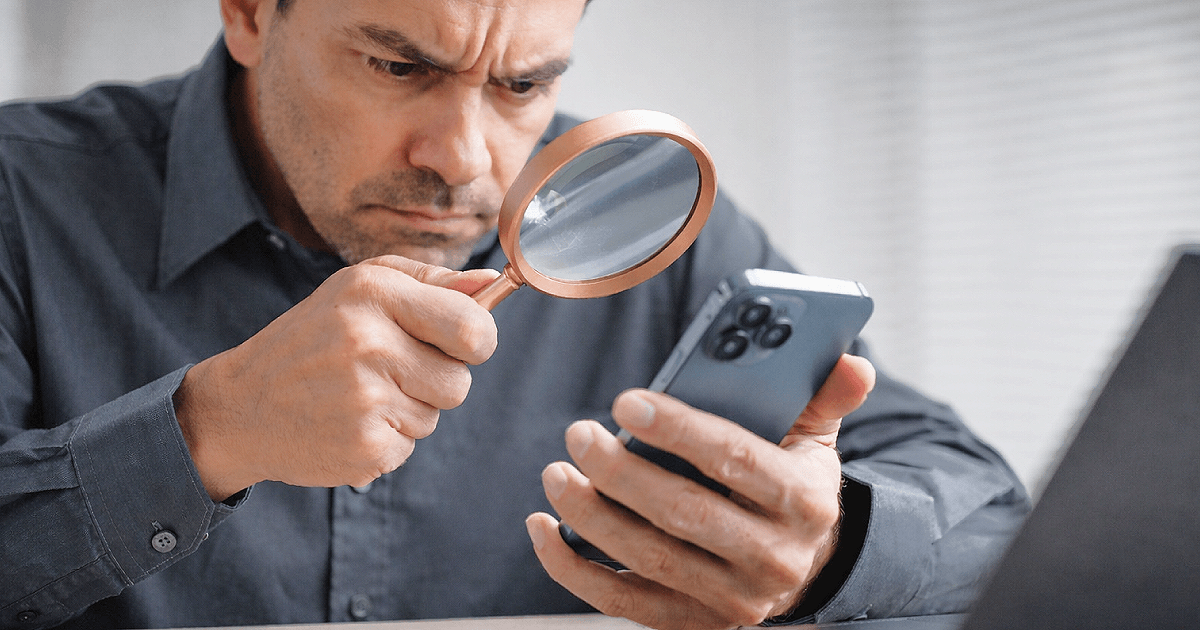

Why Manual Testing Amplifies the Problem

Manual and semi-automated testing relies heavily on subjective judgment and operator skill. Teams can be highly experienced, but repeatability drops when volumes grow or when multiple locations are involved. Different interpretations of the same defect, inconsistent test execution, and the absence of a single standard all contribute to variability that cannot be corrected downstream. Without data continuity, it becomes impossible to trace issues back to their origin or to understand why return patterns emerge.

How Accurate Diagnostics Change Business Outcomes

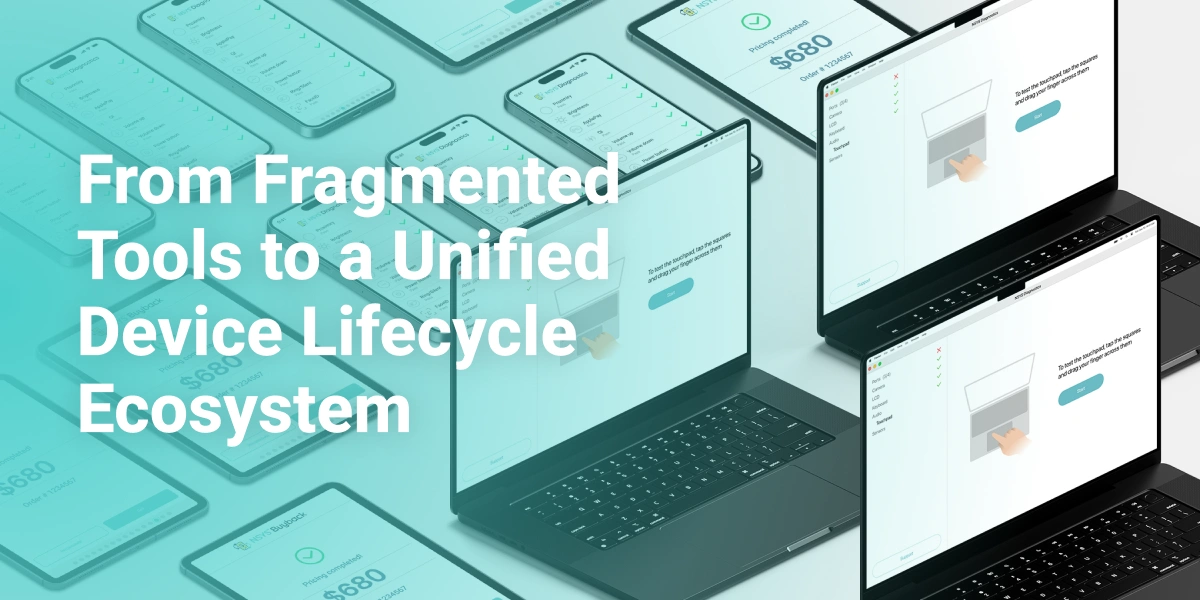

When diagnostics become stable and data-driven, the entire workflow becomes more predictable. Return rates decrease, customer disputes fall, and batches become consistent across different testing points. That consistency translates into more reliable forecasting, cleaner operational costs, and stronger client retention. This is why automated diagnostics — including solutions like NSYS Diagnostics integrated into unified operational systems — have become a cornerstone for companies seeking scalable, repeatable quality control.

By embedding diagnostics into a structured digital workflow, businesses can track every device, understand patterns behind returns, and ensure that testing is identical regardless of location or volume. The result is not only fewer losses, but also a clearer, more trustworthy product for buyers.

Conclusion: Accuracy Is a Business Strategy

In the secondary device market, buyers are not simply evaluating phones — they are evaluating the reliability of the supplier. Inaccurate diagnostics erode that reliability quietly but persistently.

The experience of companies like Eminence shows that accuracy is not an operational detail; it is a competitive advantage.To achieve this level of consistency, companies increasingly rely on diagnostic solutions built specifically for high-volume, multi-location workflows. NSYS offers an integrated toolset designed for this purpose: automated phone diagnostics, standardized quality control, and full device traceability inside a single operational ecosystem. These capabilities help teams eliminate human-driven variation, understand the origins of returns, and maintain predictable quality at scale.

For businesses processing thousands of devices, this shift is not just about improving a technical step — it is about protecting profit and reinforcing trust across every batch they ship.

If you want to see how accurate, automated diagnostics can reduce losses and improve customer confidence, request a demo of NSYS solutions and explore how they fit into your workflow.